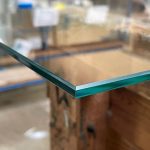

Toughened Glass

Tempered or toughened glass differs from ordinary glass in that when it breaks, it breaks into small and even pieces, greatly reducing the chance of being cut by the broken glass. This is one of the main reasons tempered glass is considered a type of safety glass, and it is widely used as a screen protector in mobile phones, coffee machines, computer screens, shower doors, and car windows, among other things.

It is not easily scratched and offers better shock protection to devices that use it as a screen.

It is smoother and clearer, and it can also withstand higher temperatures.

How is Toughened Glass Made

The majority of toughened glass is produced by tempering, a process in which ordinary glass is heated to approximately 620 degrees Celsius before being rapidly cooled.

This causes the surface to harden and contract while the core floats (remains soft) for a short time.

When the core cools, it does so in multiple layers under tensile stress, which is balanced by compressive surface stresses.

Benefits of Toughened Glass

Toughened or tempered glass has a strength that is four times that of annealed glass. Annealed glass will break at 6000 psi, while tempered glass will require a pressure of 24000 psi. Tempered glass can resist a heat of 250 degrees and this makes it safer for use in high rise apartments. It can reduce sound by 60dB. It also is able to absorb 65% of the UV rays that fall on it. Its impact resistance makes it more durable. Its versatility allows it to be used in furniture and partitions.

Disadvantages of Toughened Glass

The major disadvantage of tempered glass is that it can not be cut or resized once it has gone through the process of tempering. Hence even the drilling of holes is out of question. This requires the usage of the glass to be considered in detail and sized and worked on before it is sent for tempering. Tempered glass can also self

Rapid Emergency Glass Replacement are the glass replacement specialists in Sydney for windows, doors & shopfronts