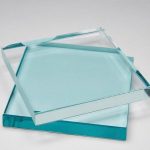

Low-iron glass is a type of high-clarity glass that can be used anywhere ordinary float glass is used.

What is low iron glass?

Float glass manufacturers produce low-iron glass, also known as extra-clear glass or optically clear glass, by reducing the amount of iron in the molten glass formula. This type is more transparent than regular glass and lacks the greenish tint. In fact, changing the iron content can increase light transparency by 5 to 6%.

How is low iron glass made?

Low iron glass is made by reducing the amount of iron in the molten glass formula, which is accomplished by using low-iron silica sand, which has a ferric oxide content of.01 percent compared to.10 percent in ordinary float glass.

What is the Difference between low iron glass and standard glass?

The primary distinction between clear glass and low iron glass is that low iron is more transparent, less green, and more aesthetically pleasing.

The superior transparency of low iron glass is a major reason for its popularity, and this type of glass looks set to remain a popular choice for those who value clarity and natural light.

Where is low iron glass used?

Low iron glass is commonly used for display cases for high-end goods such as jewellery, where clarity of the glass is critical.

Low iron glass is also useful when two different glass specifications are used in the same installation.

There will be a slight difference in colour if a thicker glass pane is placed next to a thinner one.

A solution to this problem is to use low iron glass for the thicker glass elements but not the thinner ones, giving them the same level of clarity for a consistent look.

Rapid Emergency Glass Replacement are the glass replacement specialists in Sydney for windows, doors & shopfronts